Untuk mendapatkan informasi lebih lengkap tentang:

Sylvac S-Scan 52 Horizontal Optical Measuring Machine

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

Sylvac S-Scan 52 Optical Measuring Machine is the first horizontal machine specially designed to measure rounded-parts with diameters from 0.25 mm up to 50 mm (80 mm on request) and up to 500 mm long. Sylvac S-Scan 52 works using the drop shadow principle; the device makes an optical scan of the component to produce a highly magnified, high-resolution image, on which it measures dimensions such as lengths, diameters, angles, radii, chamfers, threads, etc. There is also a component rotation system so that any form errors such as runout, cylindricity, etc. can be measured. You can also use this device for improvised gaging rig with Sylvac's gaging multiplexer software.

Sylvac S-Scan 52 Optical Measuring Machine is suitable for first-off part, control in process (SPC), sampling or 100% inspection. Sylvac S-Scan 52 Optical Measuring Machine incorporates high resolution CCD sensors that combine 2 x 7.000 elements linear arrays, with a patented 7.5° system, which would correspond to a camera within a resolution of 200 megapixels. As the part profile is projected, these sensors, which are capable of detecting the slightest changes at pixel level, act as a light sensitive rule. The contour of the workpiece is reproduced in shadow image on the software and all the various elements shown can be measured static (without part rotation) or in dynamic (with part rotation) when geometrical features such as run-out or concentricity must be measured.

Your investment on the new Sylvac S-Scan 52 Optical Measuring Machine will unlocks the higher level of precision without the additional cost on human resources. Compared to conventional bench center, traditional jig which relies on operator expertise and consumables such as dial gauge to operate, Sylvac S-Scan 52 optical measuring machine give you a competitive edge with instant return, especially when working on critical cylindrical concentricity components, such as aerospace drive shaft, electrical motors, drills and cutting tools, automotive shafts, medical device, connectors, dental screws and implants, hydraulics parts, rollers, turbines parts, CNC turned parts, etc. Various thread types and features can also be measured and analyzed with our Sylvac S-Scan 52.

Sylvac S-Scan 52 Horizontal Optical Measuring Machine Features:

- Zero consumable

- Measuring range up to Ø52mm and L300mm, with or without rotary headstock

- Suitable upgrade for your old profile projector, optical measuring scope, bench center, and multi-gauging bench.

- Automatic measurement, simply put the work-piece on the S-SCAN machine, press the button and let the Sylvac S-Scan 52 scans all the values automatically without any pre-programing necessary.

- Higher precision than manual measurement such as conservative bench center, precision comparator jig and also has the advantage of being an automatic, reduce irregularity caused by human factor.

- Faster auto-calibration for daily routines without fiddly set up and costly multi-gauge maintenance and calibration fee as with conventional measuring systems.

- Delivered with software Sylvac Reflex Click, the measuring system that makes everyone an expert!

- Single inspection report promised faster workflow, compared to jigs and bench center which combine various instrument and items of equipment to check all the parameters.

- On request, an automatic feed robot can be linked to the machine to create an automatic inspection unit that does not require an operator.

Sylvac S-Scan 52 Horizontal Optical Measuring Machine On Standard Delivery:

- Instrument according to technical specifications

- 2 male centers

- Computer, Mouse, Keyboard, Screen, Windows multilingual operating system

- Manual book

- Reflex-Scan Software

- Rotary headstock (model 902-5521 only)

SPESIFIKASI Sylvac S-Scan 52 Horizontal Optical Measuring Machine

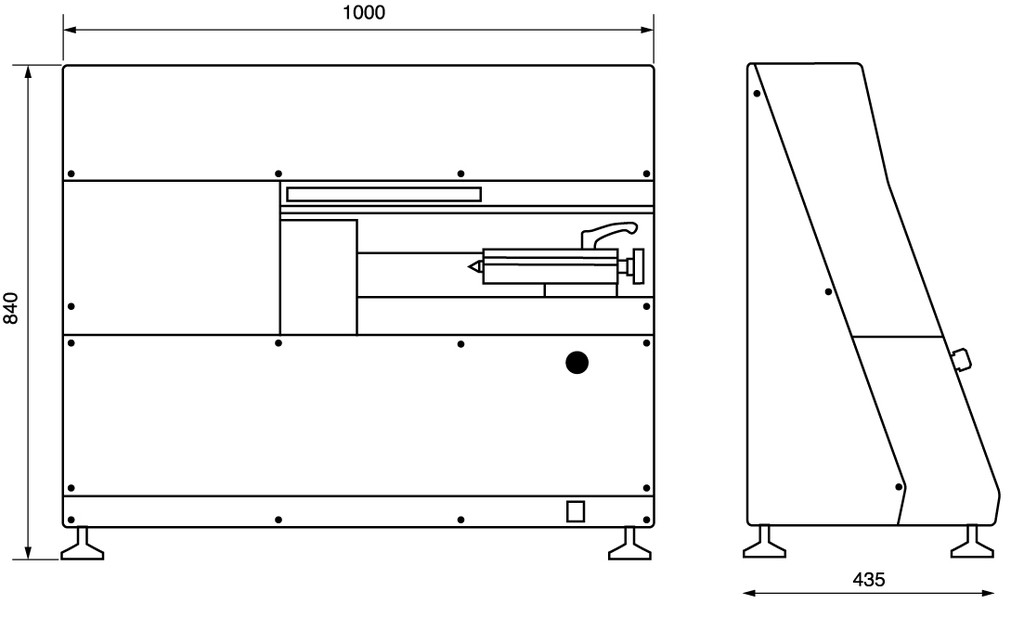

Sylvac S-Scan 52 Optical Measuring Machine Dimension:

Sylvac S-Scan 52 Optical Measuring Machine Ordering Guide:

| 810.1556 | 810.1558 | ||||

| Diameter | Length | Diameter | Length | ||

| Measuring range | mm | 0.5 / 52 | 300 | 0.5 / 52 | 300 |

| Resolution up to | mm | 0.0001 | 0.0005 | 0.0001 | 0.0005 |

| Max. Error | µm | 1.5 + D/100 | 4 + L/100 | 1.5 + D/100 | 4 + L/100 |

| Repeatability | µm | 0.6 | 2.5 | 0.6 | 2.5 |

| Headstock | Non-Rotating headstock for static measurements | Rotary headstock for static and dynamic measurements | |||

| Max. weight of part | kg | 4 | |||

| Machine's weight | kg | 103 | |||

Harga Sylvac S-Scan 52 Horizontal Optical Measuring Machine

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.