Untuk mendapatkan informasi lebih lengkap tentang:

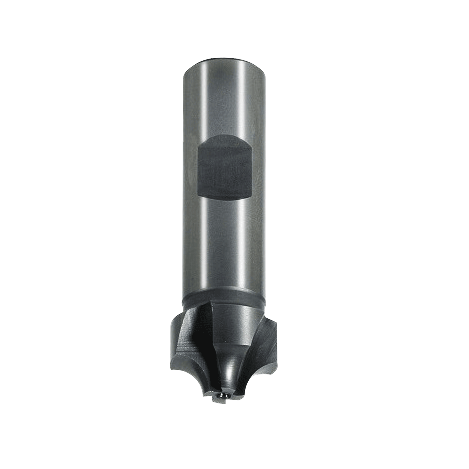

Widia 4 Flute End mill - VariMill I™ 4777 Series

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

Widia High-Performance Solid Carbide End MillsH/P Solid Carbide • VariMill™MetricSeries 4777 • VariMill • Victory™ Grades

Widia Solid Carbide End Mills are made of Widia patented micro-grain-carbide which produces higher toughness, hardness and bending strength. After acquisition by Kennametal, Widia is now capable of combining manufacturing prowess of Widia's typical HSS-Cobalt with the most up-to-date coating technology of aluminium titanium nitride (AlTiN; for aluminium contents higher 50 at.%). The innovative combination stands for a group of metastable hard coatings consisting of the metallic elements aluminium and titanium, and nitrogen for your stability and wear resistance with a higher surface quality of the material to be machined.

WIDIA™ Victory™ is the new benchmark for High-Performance Solid End Milling, giving you a solid performance advantage. Thanks to the combination of the highest concentricity accuracy and multi layered coating on shank, you can have increased oxidation resistance at elevated temperatures due to the formation of a protective aluminium-oxide layer at the surface. Furthermore, Widia WP15PE series are dedicated for Steels and Stainless Steels while the WS15PE series from Widia are made for High-Temp alloys, Titanium, and Stainless Steels from rigid and tempered casting.

Your investment on Widia Solid Carbide End Mills will allow you to take on various job of slotting, peripheral, ramping, plunging, machine the slot width using a circular movement or trochoid method on high-speed machining. With smarter application of cutting parameter and reliable machinery, you can work all the way to Fine-finishing, finishing, rough finishing and roughing with the same tool Different spiral angles (38°).

Widia Solid Carbide End Mill Features:

- Unequal flute spacing for centre cutting with helical cutting angles of 38°.

- Suitable for all-round slotting, corner radius, square ends, corner chamber, ramping, plunging, trochoidal milling with high-speed machining

- Cutting surface with odds number up to 7 flutes with straight shank, weldon shank and the new duo-lock shank, Safe-Lock™ (Safe-λock®; S-λ®) System.

- Built on the market-leading high-performance WIDIA-™ geometries, simply upgrade your existing geometry to the new Victory grades and increase your productivity.

- AlTiN coating increased hardness in the freshly deposited films due to micro-structure changes and solid solution hardening.

- Increased oxidation resistance at elevated temperatures due to the formation of a protective aluminium-oxide layer at the surface

- Broad application across multiple platforms, radii, and necked tools for maximum flexibility

SPESIFIKASI Widia 4 Flute End mill - VariMill I™ 4777 Series

Widia 4 Flute End mill - VariMill I™ 4777 Series Application Guide:

| End Mill Tolerances | |||

|---|---|---|---|

| D1 | tolerance e8 | D | tolerance h6 + / - |

| ≤ 3 | -0,014/-0,028 | ≤ 3 | 0/-0,006 |

| > 3-6 | -0,020/-0,038 | > 3–6 | 0/-0,008 |

| > 6–10 | -0,025/-0,047 | > 6–10 | 0/-0,009 |

| > 10–18 | -0,032/-0,059 | > 10–18 | 0/-0,011 |

| > 18–30 | -0,040/-0,073 | > 18–30 | 0/-0,013 |

Widia 4 Flute End mill - VariMill I™ 4777 Series Ordering Guide:

| order number | WP15PE | WP15PE | Adapter Style Machine Side | D1 | D | length of cut Ap1 max | length L | Rε | BCH |

|---|---|---|---|---|---|---|---|---|---|

| 5576753 | 477704001T | Straight-Cylindrical | 4,0 | 6 | 12,00 | 55 | 0,20 | — | |

| 5576751 | 477704002T | Straight-Cylindrical | 4,0 | 6 | 12,00 | 55 | — | 0,40 | |

| 5576752 | 477704002W | Weldon | 4,0 | 6 | 12,00 | 55 | — | 0,40 | |

| 5576754 | 4777040Z2T | Straight-Cylindrical | 4,0 | 6 | 12,00 | 55 | — | — | |

| 5576755 | 477705002T | Straight-Cylindrical | 5,0 | 6 | 13,00 | 57 | — | 0,40 | |

| 5576756 | 477705002W | Weldon | 5,0 | 6 | 13,00 | 57 | — | 0,40 | |

| 5576757 | 477705012T | Straight-Cylindrical | 5,0 | 6 | 13,00 | 57 | 0,20 | — | |

| 5576758 | 4777050Z2T | Straight-Cylindrical | 5,0 | 6 | 13,00 | 57 | — | — | |

| 5576759 | 477706002T | Straight-Cylindrical | 6,0 | 6 | 13,00 | 57 | — | 0,40 | |

| 5576760 | 477706002W | Weldon | 6,0 | 6 | 13,00 | 57 | — | 0,40 | |

| 5576761 | 477706012T | Straight-Cylindrical | 6,0 | 6 | 13,00 | 57 | 0,20 | — | |

| 5576762 | 4777060Z2T | Straight-Cylindrical | 6,0 | 6 | 13,00 | 57 | — | — | |

| 5576763 | 477707003T | Straight-Cylindrical | 7,0 | 8 | 16,00 | 63 | — | 0,40 | |

| 5576764 | 477707003W | Weldon | 7,0 | 8 | 16,00 | 63 | — | 0,40 | |

| 5576765 | 477707013T | Straight-Cylindrical | 7,0 | 8 | 16,00 | 63 | 0,20 | — | |

| 5576766 | 4777070Z3T | Straight-Cylindrical | 7,0 | 8 | 16,00 | 63 | — | — | |

| 5576767 | 477708003T | Straight-Cylindrical | 8,0 | 8 | 16,00 | 63 | — | 0,40 | |

| 5576768 | 477708003W | Weldon | 8,0 | 8 | 16,00 | 63 | — | 0,40 | |

| 5576769 | 477708013T | Straight-Cylindrical | 8,0 | 8 | 16,00 | 63 | 0,20 | — | |

| 5576770 | 4777080Z3T | Straight-Cylindrical | 8,0 | 8 | 16,00 | 63 | — | — | |

| 5576771 | 477709004T | Straight-Cylindrical | 9,0 | 10 | 19,00 | 72 | — | 0,50 | |

| 5576772 | 477709004W | Weldon | 9,0 | 10 | 19,00 | 72 | — | 0,50 | |

| 5576773 | 477709014T | Straight-Cylindrical | 9,0 | 10 | 19,00 | 72 | 0,20 | — | |

| 5576774 | 4777090Z4T | Straight-Cylindrical | 9,0 | 10 | 19,00 | 72 | — | — | |

| 5576775 | 477710004T | Straight-Cylindrical | 10,0 | 10 | 22,00 | 72 | — | 0,50 | |

| 5576776 | 477710004W | Weldon | 10,0 | 10 | 22,00 | 72 | — | 0,50 | |

| 5576777 | 477710024T | Straight-Cylindrical | 10,0 | 10 | 22,00 | 72 | 0,30 | — | |

| 5576778 | 4777100Z4T | Straight-Cylindrical | 10,0 | 10 | 22,00 | 72 | — | — | |

| 5576779 | 4777110Z5T | Straight-Cylindrical | 11,0 | 12 | 26,00 | 83 | — | — | |

| 5576790 | 477712005T | Straight-Cylindrical | 12,0 | 12 | 26,00 | 83 | — | 0,50 | |

| 5576791 | 477712005W | Weldon | 12,0 | 12 | 26,00 | 83 | — | 0,50 | |

| 5576792 | 477712025T | Straight-Cylindrical | 12,0 | 12 | 26,00 | 83 | 0,30 | — | |

| 5576793 | 4777120Z5T | Straight-Cylindrical | 12,0 | 12 | 26,00 | 83 | — | — | |

| 5576795 | 477714014W | Weldon | 14,0 | 14 | 26,00 | 83 | — | 0,50 | |

| 5576794 | 477714015T | Straight-Cylindrical | 14,0 | 14 | 26,00 | 83 | — | 0,50 | |

| 5576796 | 477716006T | Straight-Cylindrical | 16,0 | 16 | 32,00 | 92 | — | 0,50 | |

| 5576797 | 477716006W | Weldon | 16,0 | 16 | 32,00 | 92 | — | 0,50 | |

| 5576798 | 477716026T | Straight-Cylindrical | 16,0 | 16 | 32,00 | 92 | 0,30 | — | |

| 5576799 | 4777160Z6T | Straight-Cylindrical | 16,0 | 16 | 32,00 | 92 | — | — | |

| 5576810 | 477718018T | Straight-Cylindrical | 18,0 | 18 | 32,00 | 92 | — | 0,50 | |

| 5576811 | 477718018W | Weldon | 18,0 | 18 | 32,00 | 92 | — | 0,50 | |

| 5576812 | 477720007T | Straight-Cylindrical | 20,0 | 20 | 38,00 | 104 | — | 0,50 | |

| 5576813 | 477720007W | Weldon | 20,0 | 20 | 38,00 | 104 | — | 0,50 | |

| 5576814 | 47772002T | Straight-Cylindrical | 20,0 | 20 | 38,00 | 104 | 0,30 | — | |

| 5576816 | 477725008T | Straight-Cylindrical | 25,0 | 25 | 45,00 | 121 | — | 0,50 | |

| 5576817 | 477725008W | Weldon | 25,0 | 25 | 45,00 | 121 | — | 0,50 |

|

NOTE: Lower value of cutting speed is used for high stock removal applications or for higher hardness (machinability) within group. Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group. Above parameters are based on ideal conditions. For smaller taper machining centres, please adjust parameters accordingly on >12mm diameters. |

Harga Widia 4 Flute End mill - VariMill I™ 4777 Series

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.